In the global steel industry, continuous casting technology stands at the heart of efficient production. The process has evolved significantly over the years, driven by innovations that enhance quality, reduce defects, and increase production rates. One of the most transformative advancements is the use of electromagnetic stirrers (EMS), and Samrudhi Engineers has positioned itself as a pioneer in providing state-of-the-art EMS solutions for continuous casting operations worldwide.

The Importance of Electromagnetic Stirring in Continuous Casting

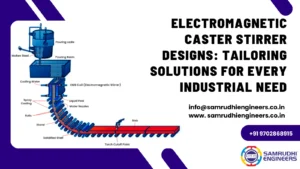

Continuous casting involves solidifying molten steel into semi-finished billets, blooms, or slabs for subsequent processing. Uniform solidification is critical to ensuring high-quality output with minimal defects such as segregation, porosity, and cracks. This is where electromagnetic stirring plays a pivotal role.

Electromagnetic Stirrers for Continuous Casting generate a controlled magnetic field that induces stirring in the molten steel. This movement disrupts dendritic growth, promotes uniform solidification, and helps in distributing solute elements more evenly. Key benefits of electromagnetic stirring include:

Reduced centerline segregation: Stirring mitigates the concentration of solutes at the centerline, enhancing the mechanical properties of the final product.

Minimized porosity and cracks: The homogeneous solidification reduces internal defects, improving structural integrity.

Enhanced surface quality: Consistent solidification leads to smoother surfaces, reducing the need for secondary processing.

Samrudhi Engineers: Innovators in Electromagnetic Stirrers for Continuous Casting

Samrudhi Engineers brings unparalleled expertise in designing and delivering customized electromagnetic stirring solutions. Their systems are specifically engineered to integrate seamlessly with the most advanced continuous casters, ensuring optimum performance and maximum productivity.

Key features of Samrudhi Engineers’ Electromagnetic Stirrers for Continuous Casting:

1. Advanced Magnetic Field Control

Samrudhi Engineers employs cutting-edge technology to generate precise magnetic fields. This precision ensures consistent stirring intensity tailored to the specific metallurgical needs of each casting process.

2. Customizable Designs

Every caster is unique, and Samrudhi’s EMS solutions are fully customizable. They offer a range of stirrers, including:

Mold electromagnetic stirrers (MEMS): Positioned at the mold level to ensure uniform initial solidification.

Final stirrers: Installed downstream to maintain uniformity as the steel fully solidifies.

These configurations are optimized to enhance performance for various steel grades and caster designs.

3. Energy Efficiency

Samrudhi Engineers focuses on delivering solutions that maximize energy efficiency without compromising on performance. Their EMS systems utilize advanced power electronics to minimize energy consumption while providing robust stirring power.

4. Real-Time Monitoring and Control

Modern continuous casting demands precision, and Samrudhi Engineers equips its stirrers with real-time monitoring systems. Operators can track performance metrics and adjust parameters on-the-fly, ensuring consistent quality.

Case Study: Electromagnetic Stirring for a High-Performance Slab Caster

One of the standout applications of Samrudhi Engineers’ EMS solutions is in a state-of-the-art slab caster commissioned by a leading global steel manufacturer. This continuous caster, designed for ultra-high throughput and specialized steel grades, required an EMS system capable of delivering unmatched performance.

Challenges Faced

High production speed: The caster’s high-speed operation posed challenges for uniform solidification.

Stringent quality requirements: The steel grades produced demanded minimal segregation and flawless surface finish.

Energy optimization: With sustainability goals in focus, energy efficiency was a critical requirement.

Samrudhi Engineers’ Solution

To meet these challenges, Samrudhi Engineers delivered a customized electromagnetic stirring solution comprising:

High-performance mold stirrers: Designed to enhance initial solidification consistency.

Optimized final stirrers: Configured for uniform grain refinement and reduced defects in the final solidification phase.

Advanced control systems: Integrated real-time control for precise adjustments based on casting speed and steel grade.

Results Achieved

Improved quality: The use of EMS significantly reduced centerline segregation and internal porosity.

Energy savings: Efficient power management resulted in substantial energy cost reductions.

Higher productivity: The continuous caster achieved greater throughput with minimal downtime.

Why Choose Samrudhi Engineers for Electromagnetic Stirring Solutions?

Samrudhi Engineers combines innovation, customization, and industry expertise to deliver EMS systems that set new standards in continuous casting technology. Key reasons to partner with them include:

Proven track record: Successful installations in leading steel plants worldwide.

Tailored solutions: Systems designed to meet the specific needs of each caster.

Commitment to quality: High-performance systems built with precision engineering.

Ongoing support: Comprehensive service and maintenance to maximize equipment life.

The Future of Continuous Casting with Samrudhi Engineers

As the global steel industry continues to innovate, the demand for advanced technologies in continuous casting will only grow. Electromagnetic stirring will remain a critical component for enhancing productivity, quality, and sustainability. Samrudhi Engineers is poised to lead this transformation with ongoing advancements in EMS technology, ensuring their clients stay ahead in a competitive market.

Conclusion

Electromagnetic stirring is a game-changer for continuous casting, and Samrudhi Engineers is at the forefront of delivering solutions that redefine performance standards. By integrating cutting-edge design, energy efficiency, and precision control, they empower steel manufacturers to achieve unparalleled quality and efficiency. Whether it’s for billets, blooms, or slabs, Samrudhi Engineers’ EMS solutions are setting the benchmark for modern continuous casting technology.