EMS Coil (Electromagnetic stirrers)

along with the assurance of continuous support from our team

EMS Coil (Electromagnetic stirrers COIL)

EMS Coil (Electromagnetic stirrers)

EMS Coil (Electromagnetic stirrer) refers to a technique, through which it is possible to achieve stirring efficiency of a higher level, through the interaction between the electrical metal bath and magnetic field. EMS offers a plethora of benefits such as enhanced manufacturing yields, enhanced startup, and faster financial payback. There is a considerable reduction in the defects of the finished product, thereby improving the efficiency.

EMS Coil (Electromagnetic stirrers) have found extensive use in the industries for continuous casting, Billet Caster, Slab Caster and ladle furnaces. There is a considerable improvement in the product quality and a rise in steel production with the use of these stirrers.

Benefits

- An increase in the central soundness

- Energy efficient

- Structure improvement solidification

- Sub-surface quality and surface enhancer

- Customized design on the previous and new CMM

We at Samrudhi Engineers bring you the best-in-class EMS Coil (electromagnetic stirrer coil), catering to your needs. We have gained a high reputation in manufacturing the EMS coils of high excellence. We have several years of experience in this field. The leading industries prefer to choose our products because the stirrer decreases the white porosity bonds strongly. They are known for their ever-lasting insulation. As they do not break down easily, you can maintain them easily.

Mould Electromagnetic Stirrer Coil (M-EMS)

Strand Electromagnetic Stirrer Coil(S-EMS)

Usage of clean water in the EMS: The EMS installed within make use of a separate cooling water system, making the structure both durable and reliable. Stirring freq: 2 ~ 8Hz.

Final Electromagnetic Stirrer Coil (F-EMS)

Using a separate cooling water mechanism, the EMS is setup outside the mould. Here, the process of changing the copper tube is simple. Plus, the EMS can be utilized for various sections. Stirring freq: 2 ~ 5Hz.

Linear Electromagnetic Stirrer Coil (L- EMS)

Along with rotating magnetic field, long iron core is used by F-EMS. Here, we get wider application range along with a powerful magnetic induction. Intermittent or alternating stirring system is used for the stirring effect.

Slab Electromagnetic Stirrer Coil

Long iron core and rotating magnetic field are both utilised by F-EMS. Here, a broader application range and a strong magnetic induction are provided. The stirring effect is achieved using an intermittent or alternating stirring method.

Services We Offer

Manufacturing

Rewinding

Reconditioning & Repairing

All Spares

ELECTROMAGNETIC STIRRER FOR BILLET CASTERS

- Strand Electromagnetic Stirrer

- Mould Electromagnetic Stirrer

- Final Electromagnetic Stirrer

There will be an increase in the production in the industries as you choose our electromagnetic stirrer coils. These coils have also found extensive use in the iron and steel sector as they enhance the production and quality of steel.

BENEFITS

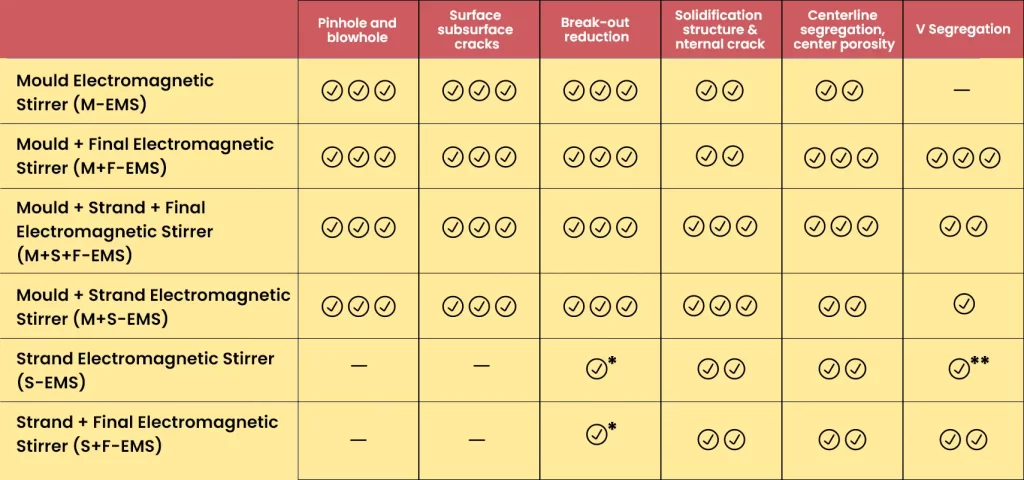

The benefits obtained using one or more EMS in combination are summarized in the table.

*With S-EMS in high position. ** With S-EMS in low position.