In the highly competitive and environmentally conscious world of steel manufacturing, improving efficiency while minimizing waste is not just a goal—it’s a necessity. One of the most impactful innovations in this sector is Electromagnetic Stirring (EMS), particularly the use of EMS coils. These specialized components are designed to optimize the solidification process during continuous casting, resulting in better metal quality, reduced defects, and higher operational productivity.

samrudhi Engineers, a trusted name in industrial engineering solutions, provides advanced EMS coil systems tailored to enhance steelmaking processes.

What Are EMS Coils?

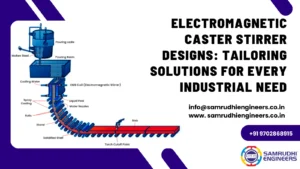

EMS coils are induction-based devices used in continuous casting machines to create a controlled magnetic field. This field stirs molten steel during solidification. The stirring action encourages uniform temperature and composition distribution, leading to better internal quality and grain structure in the cast product.

Samrudhi Engineers specializes in custom-designed EMS coils that cater to both high-speed and high-temperature casting operations, ensuring compatibility with various steel grades and casting configurations.

The Role of EMS in Steel Manufacturing

In the continuous casting process, molten steel is poured into a mold and gradually solidifies as it moves downward. Without proper stirring, issues like centerline segregation, porosity, and uneven grain structure can occur.

EMS coils introduce a non-contact stirring force, using a magnetic field to:

Enhance dendritic fragmentation

Homogenize temperature and solute distribution

Control the flow pattern within the solidifying steel

As a result, Samrudhi Engineers’ EMS coil systems contribute to superior metallurgical quality and consistent casting performance.

Benefits of EMS Coils in Productivity Enhancement

a. Improved Internal Quality

EMS coils help eliminate common casting defects like macrosegregation, shrinkage cavities, and cracks—reducing the need for post-casting inspections and repairs.

b. Increased Casting Speed

Uniform solidification allows for higher withdrawal speeds, which means more steel is cast in less time. Solutions from samrudhiengineers are built to support high-efficiency production lines.

c. Enhanced Yield

Reducing surface and internal defects translates to less rejection of final products, thereby improving the overall yield.

d. Consistency Across Casts

The automated and repeatable nature of electromagnetic stirring ensures consistent product quality, which is essential for downstream processes like rolling or forging.

How EMS Coils Reduce Waste

EMS coils contribute significantly to waste reduction in several ways:

Minimized Internal Defects: With better metallurgical structure, the scrap rate is lowered.

Reduced Alloy Waste: Homogenized mixing decreases the overuse of expensive alloying elements.

Lower Energy Consumption: Efficient casting reduces the energy required for rework or reheating.

Cleaner Cuts and Fewer Surface Defects: Reduced need for grinding or cropping.

Samrudhi Engineers helps steel manufacturers implement EMS systems that align with zero-waste and sustainability initiatives.

Key Applications in Continuous Casting

EMS coils are used in casting machines for:

Billets (long steel products)

Blooms (larger square sections)

Slabs (used for rolling into flat products)

They are particularly vital in:

High-carbon steels

Alloyed steels

Peritectic steels

Samrudhi Engineers offers solutions for each of these applications, designed to withstand harsh environments while delivering precision stirring for various steel compositions.

Challenges and Maintenance Considerations

While EMS coils are powerful tools, they come with considerations:

Initial Setup Cost: Installation and integration into existing systems can be capital-intensive.

Coil Degradation: Prolonged use under high temperatures can lead to coil wear or insulation breakdown.

Control System Synchronization: Proper tuning with the casting process is essential to avoid turbulence.

Samrudhi Engineers provides ongoing technical support, installation guidance, and maintenance services to ensure uninterrupted EMS performance.

The Future of EMS in Sustainable Steelmaking

As the steel industry embraces decarbonization and digitalization, EMS coils are poised to play an even greater role. Future innovations include:

Smart EMS systems with real-time feedback and AI-driven control.

Hybrid stirring systems combining electromagnetic and mechanical stirring.

Modular coil designs for flexible plant retrofitting.

Samrudhi Engineers is actively investing in R&D to deliver next-generation EMS solutions that align with green manufacturing standards.

FAQs

EMS stands for Electromagnetic Stirring, a technique used to stir molten steel during the casting process to improve quality and reduce defects.

EMS coils generate a magnetic field that induces flow in molten steel, leading to uniform temperature and composition during solidification.

Yes, many EMS coil systems are designed for modular integration, and Samrudhi Engineers offers custom solutions for retrofitting older machines.

Absolutely. Routine inspections, cooling system checks, and recalibration are essential. Samrudhi Engineers offers comprehensive after-sales support and maintenance services.

By minimizing casting defects, reducing the need for alloying corrections, and improving yield, EMS coils contribute directly to lower scrap rates and resource waste.

Conclusion

EMS coils are more than just auxiliary components—they are key enablers of efficiency, quality, and sustainability in modern steel manufacturing. From reducing internal defects to enhancing throughput, these coils bring both environmental and economic value. As steel producers strive for cleaner and more competitive operations, EMS technology—backed by leaders like Samrudhi Engineers—will undoubtedly remain at the heart of industrial innovation.