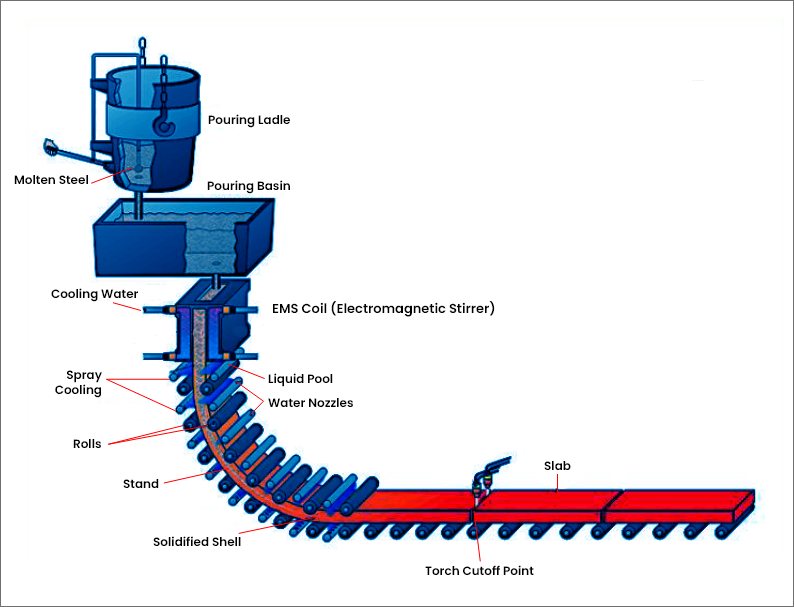

EMS, or electromagnetic stirring, contributes to the process through which it is possible to achieve the stirring efficiency of a higher level through the interaction between the magnetic field from the electrically conducting metal bath and the static induction coil.

From the experimental study and the practical implementation, the EMS results offer extensive benefits, which are inclusive of the higher manufacturing yields, finished product defects reduction, faster startup, and faster financial payback to improve the efficiency.

What is electromagnetic stirring?

Electromagnetic stirring (EMS) happens to be a well-known technique, which is used in the copper and steel alloys’ grain refinement industrially. It is known to be effective in MG-based and Al-based alloys’ grain refinement.

According to the most recent research on electromagnetic solidification and electrostatic solidification, melt flow is critical for the attendant equiaxed grain formation due to dendrite fragmentation. The limited evidence suggests that intense electromagnetic stirring beyond the threshold inducing nucleation, which can be achieved via cavitation impacts, is recommended. As you gain an understanding of the specific electromagnetic solicitation mechanics, it will enhance the electromagnetic stirring’s application.

The electromotive force's application in continuous casting

Electromagnetic stirring (EMS) in the strand and mould is useful in slab casting, bloom, and billet. Apart from this, the electromagnetic brake is used on an exclusive scale to cast slabs. Such technologies are meant to improve the cast structure control and the steel quality. The steel engineer wishes to develop a process that will mimic the specific technologies used in copper and aluminum processing.

Here, the Lorentz force is used on a wide scale to control the meniscus position in the mold and prevent the meniscus solidification. Thus, the continuous cast surfaces are developed, which are free from different kinds of oscillation marks. So, you can be sure that the continuous cast surfaces are defect-free and smooth. This kind of technology will result in the removal of the surface grinding and different treatments, which are used to assure the surface quality.

If you want to decrease the induced meniscus fluid flow, the pulsative electromagnetic field is used to be employed, which decreases the inducted meniscus flow and allows the stabilized meniscus region.

Such a development enables the successful implementation of the specific technology on the traditional billet caster, where there is a considerable improvement in the surface roughness. In addition, it enables the elimination of the oscillation mark depth and the billet surface conditioning. Thus, the pulsative technology used to be trialed on the slab caster with similar types of positive results.

Role of EMS or electromagnetic stirrers

With the latest developments in technology and science, EMS, or electromagnetic stirring, is used on a wide scale. There are a wide assortment of industrial operations and metallurgical practises which prove that the EMS system’s continuous casting machine improves the strand’s internal structure.

Moreover, it plays an integral role in bringing an improvement in the surface quality. In addition, it decreases the centre porosity and the centre segregation, removes the centre shrinkage, cracks, and boosts the equiaxed grain rate. Thus, it allows you to lower the continuous casting process and enhance the casting speed.

But the continuous casting technique conditions will impact the metallurgical effects significantly. Hence, you should consider the metallurgical quality control from the continuous caster’s metallurgical theory and the metallurgical process on its own. Thus, the electromagnetic stirrer or EMS systems reduce the process measurement needs.

The strand's internal quality S-EMS improvement

The S-EMS, or secondary cooling zone electromagnetic stirrer, contributes to being the electromagnetic stirrer, which is installed within the secondary cooling zone. Such a kind of current will pass via the electromagnetic stirrer for the generation of the alternating magnetic field. This kind of alternative magnetic field reduces the conductor for the production of the electromagnetic force.

Such kinds of molten steel allow the circulation in the specific direction under the electromagnetic force’s action, which helps achieve the purpose of the motel steel and uniform temperature objectives. Thus, it helps to boost the strand’s average grain rate.

The S-EMS’s installation position happens to be the area where the strand’s unconsolidated rate will be in the range of 50–40 percent. Such a position will be at the end part of the mold’s electromagnetic stirring flow field impacts. The strand shell will be thick and there is not going to be any bulging.

The strand's M-EMS improvement quality

The M-EMS, or mold electromagnetic stirrer, gets installed within the mould zone. The unsoldified molten steel’s movement will be accelerated through the electromagnetic force, which is produced by the electromagnetic stirring. Thus, it changes the heat transfer, changes the flow, and the molten steel’s migration process during the solidification process.

It plays an integral role in enhancing the strand quality. In addition, it helps in controlling the subsurface quality and surface quality, which decreases the blowhole, the inclusions, and the airhole.

The electromagnetic stirrers enhance the grain zone’s equiaxed. It decreases porosity and segregation to a specific extent. If you find that the mold’s stirring speed is extremely high, there will be a fluctuation in the meniscus and the nozzle will be washed. It leads to serious erosion of the nozzle. Hence, it is necessary to take the stirring intensity into account.

The strand's internal quality's F-EMS

For specialized steels like the high alloy steel and high-carbon steel, issues like center cracks, center shrinkage, center segregation is produced at the end part of the so-called mushy zone. If you want to resolve such issues, the F-EMS or final electromagnetic stirrer contributes to being the efficient technique. Owing to the F-EMS needs to resolve the metallurgical issues, it is essential to install the F-EMS’s installation position.

It is recommended to install the final electromagnetic stirrer for the high carbon steel’s billet in the specific area where the unsolidified rate will be in the range of 25-33 percent section length ratio. The casting speed will affect the final solidification’s position. Hence, it is crucial to maintain the casting speed’s stability. Samruddhi Engineers is one of the leading companies, which helps to develop the EMS or electromagnetic stirrers on a wide scale.