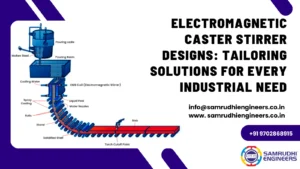

In industries like metallurgy, manufacturing, and chemical processing, stirring systems play a crucial role in maintaining efficiency, consistency, and product quality. A well-maintained stirring system ensures optimal material mixing, prevents defects, and extends the equipment’s lifespan. Samrudhi Engineers specializes in comprehensive stirring system maintenance services, ensuring your operations run smoothly without unexpected downtimes.

Importance of Stirring System Maintenance

Regular maintenance of stirring systems is essential for:

Enhancing Efficiency: A properly maintained system ensures uniform mixing and energy efficiency.

Preventing Downtime: Timely servicing helps avoid unplanned shutdowns and costly repairs.

Ensuring Product Quality: Poorly maintained stirrers can lead to inconsistent material properties and defects.

Extending Equipment Life: Routine maintenance reduces wear and tear, extending the longevity of the system.

Compliance with Safety Standards: Proper maintenance prevents accidents and ensures compliance with industry regulations.

Comprehensive Stirring System Maintenance Services by Samrudhi Engineers

1. Routine Inspection & Performance Assessment

Our experts conduct regular inspections to identify early signs of wear, misalignment, or inefficiencies in the stirring system. This includes:

Checking motor functionality

Analyzing blade conditions

Inspecting bearings and seals

Monitoring temperature and vibration levels

Assessing overall system performance

2. Lubrication & Component Replacement

Proper lubrication reduces friction, prevents overheating, and minimizes component failure. We provide:

Lubrication of bearings, gears, and moving parts

Replacement of worn-out seals and gaskets

Servicing of motor and drive components

3. Alignment & Calibration

Improper alignment can cause inefficiencies and mechanical failures. Our services include:

Shaft and impeller alignment adjustments

Calibration of motor speed and torque settings

Balancing of mixing blades for optimal performance

4. Cleaning & Debris Removal

Over time, material buildup can hinder stirring efficiency. Our team ensures:

Thorough cleaning of mixing tanks and impellers

Removal of hardened deposits and residues

Use of non-corrosive cleaning agents to prevent equipment damage

5. Vibration Analysis & Troubleshooting

Excessive vibration is a sign of mechanical issues. Our experts conduct:

Vibration analysis to detect imbalances

Troubleshooting of abnormal sounds, leaks, or power fluctuations

Repairs or replacements of faulty components to restore smooth operation

6. Control System & Electrical Maintenance

Electrical and control systems are integral to the efficiency of modern stirring setups. We provide:

Inspection of electrical wiring and connections

Software updates for automated control systems

Repair of faulty sensors and controllers

7. Emergency Breakdown Support

Unexpected failures can disrupt operations. Our 24/7 emergency repair services ensure quick response times and minimal downtime.

Industries We Serve

Samrudhi Engineers provides stirring system maintenance solutions for a wide range of industries, including:

Metallurgy & Foundries: Ensuring uniform molten metal mixing.

Chemical Processing: Preventing contamination and improving reaction consistency.

Food & Beverage: Maintaining hygiene standards and product quality.

Pharmaceuticals: Ensuring precise ingredient mixing and compliance with health regulations.

Water Treatment: Maintaining efficient coagulation and sedimentation processes.

Why Choose Samrudhi Engineers?

Expert Technicians: Our skilled professionals bring years of experience in handling industrial stirring systems.

Advanced Diagnostic Tools: We use cutting-edge tools for real-time monitoring and predictive maintenance.

Customized Maintenance Plans: Tailored solutions to match your specific industry requirements.

Cost-Effective Services: Preventive maintenance reduces long-term repair costs.

Commitment to Safety & Compliance: We adhere to industry standards and safety protocols.

Conclusion

Efficient stirring systems are essential for maintaining consistent production quality and operational efficiency. Regular inspection, cleaning, alignment, and troubleshooting help in preventing failures and prolonging equipment life. Samrudhi Engineers is your trusted partner for comprehensive stirring system maintenance services, ensuring seamless operations and minimal downtime.

For professional stirring system maintenance solutions, contact Samrudhi Engineers today!