PUMPS

along with the assurance of top-quality service.

PUMPS

PUMPS SYSTEM

Pumps are regarded as an integral part of the industry. They play an integral role in moving the fluid controllably where the fluid is engaged through the use of the stronger rotational kinetic energy. Such energy enhances the fluid pressure throughout the pumping process. They are recognized to be budget-friendly solutions for the high-capacity and low-pressure pumping apps.

With the rise in the infrastructural development activities, there is a steady demand for the centrifugal pumps gained traction. These pumps showcase several apps as they serve the food and beverages, water and wastewater, pharmaceuticals, chemicals, seawater desalinate industries, and the oil, and gas sector.

Unmatched pump repairing and related services

Samrudhi Engineers presents the pumps of high excellence. We are considered to be the leading experts to offer, manufacture, and design the pumps of a comprehensive range. With our innovation and delivery excellence, we have gained success in retaining the already existing customers. Besides this, as the top pump manufacturers, we can lure the attention of potential customers on a wide scale.

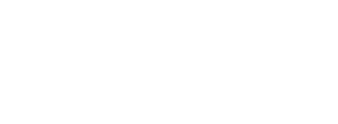

All Pump Repairing

The pump repair plays an integral role in the simplification of preventive maintenance. There are a bunch of general shop tools and a variety of screwdrivers, sockets, and wrenches which offer a helping hand in the pump repair. We are one of the leading pump repair service providers which have earned a high reputation in offering expertise and affordable pump repair system.

Clients across the industry love to choose our services as we have the eyes for the details. We invest your valuable time in maintaining strict dedication and professionalism owing to which we are considered to be the top pump manufacturer across the country. We aim to provide enhanced client satisfaction, thereby expanding the clientele, product portfolio, and reach over the years.

Mechanical Seal

Mechanical seals are recognized to be devices that offer a specific seal at the exit and entry point of the rotating shaft. It is used on a wide scale for the prevention of high-pressure fluid and to reduce pressure fluid leakage. One should take into account the requirement for a dependable and predictable mechanical seal performance given the environmental and health and safety regulations as well as the demand for increased process equipment efficiency. There are different mechanical seal types to choose from depending on the type of pump and the process variables. Each type of seal is distinct in its design and features, making it appropriate for a particular use.

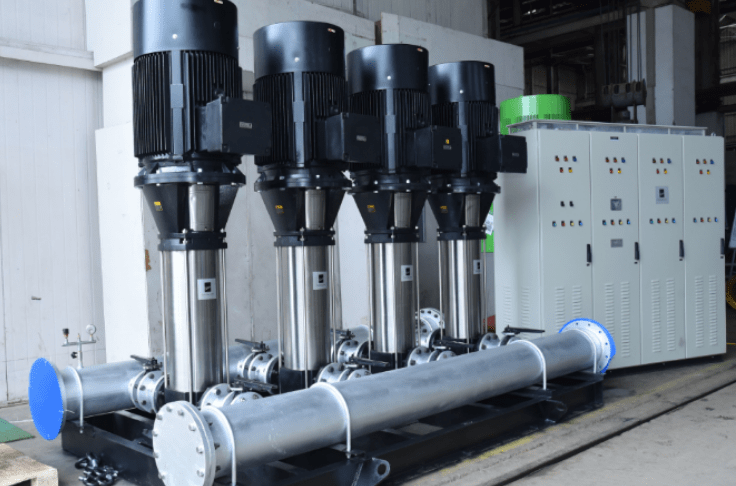

Hydro Pneumatic System

The hydropneumatic tank comprises the pressurized water and air. It does not include a bladder. Here, the water remains in contact with water directly. In addition, the compressed air served as the cushion to absorb and force the pressure. Such kind of tank helps in the delivery of water at the selected pressure rate. Hence, you can be ensured that the pump is not running consistently. There is a reduction in the pressure surges in the hydropneumatic tank systems. Tank feeding systems, curing systems, and tap feeding systems are the three major classifications of hydropneumatic systems.

All spares

The ultimate goal of All Spare System is to offer the prerequisite parts at the right place in the right quantity with the proper quality level, at the right time. As you handle the spare parts, it will lead to enhanced operating performance. Besides offering pumps of exclusive design which can accomplish enhanced flexibility, and are meant for different apps, we at Samruddi Engineers also ensure complete assistance when it comes to spare parts. Our pump suppliers prefer to choose our products owing to faster delivery, 24*7 customer support, and high quality.